The ethylene industry has its roots in the late 19th and early 20th centuries when the petrochemical industry began to take shape. Initially, ethylene was produced as a byproduct of coal gasification and later from crude oil. With the advent of modern petrochemical processing techniques, the production of ethylene increased exponentially, leading to a significant expansion of the industry.

Production Methods Ethylene is primarily produced through two methods: steam cracking and catalytic cracking. Steam cracking involves heating hydrocarbon feedstocks, such as ethane, propane, or naphtha, to high temperatures (around 800-900 degrees Celsius) in the presence of steam. This process breaks down the hydrocarbons into smaller molecules, including ethylene. Catalytic cracking, on the other hand, uses catalysts to facilitate the breakdown of larger hydrocarbon molecules into ethylene and other products.

Applications of Ethylene Ethylene's versatility makes it a key component in a range of applications. Its primary use is in the production of polyethylene, the most common plastic worldwide. Polyethylene is used in packaging, containers, plastic bags, and countless other products. Additionally, ethylene is a precursor for ethylene oxide, which is further processed into ethylene glycol, a critical component in antifreeze and polyester production.

Ethylene market is also used in the synthesis of vinyl chloride, which leads to polyvinyl chloride (PVC), widely used in construction and plumbing. Moreover, ethylene's role in agriculture cannot be understated—it acts as a plant hormone involved in fruit ripening, making it an essential component in the controlled ripening of fruits and vegetables.

Global Impact The ethylene industry has a significant impact on the global economy. As the demand for plastics and other ethylene-derived products continues to grow, countries with large ethylene production capacities, such as the United States, China, and Saudi Arabia, have established themselves as leaders in the industry. This growth has spurred investment in new ethylene production facilities, with companies continually seeking to improve efficiency and reduce environmental impact.

Environmental Challenges Despite its economic importance, the ethylene industry faces environmental challenges. The production processes for ethylene are energy-intensive and contribute to greenhouse gas emissions. Additionally, the widespread use of plastics derived from ethylene raises concerns about plastic pollution and sustainability.

To address these challenges, the industry is exploring alternative production methods, such as bio-based ethylene from renewable sources, and investing in recycling technologies to reduce plastic waste. Governments and regulatory bodies are also imposing stricter environmental regulations, pushing the industry to adopt cleaner and more sustainable practices.

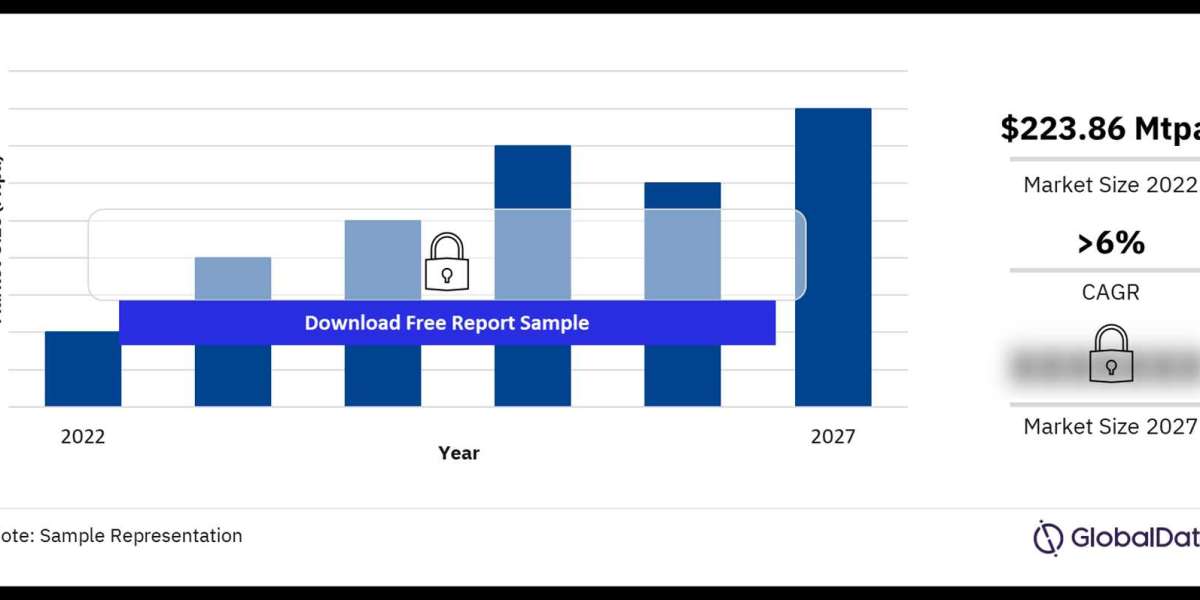

Buy the Full Report for More Insights into the Ethylene Industry Installed Capacity Forecast, Download A Free Report Sample